Salt of Stearoyl Lactate is an anionic emulsifier, which is used as a quality improvement agent for mainly bread and confectionery.

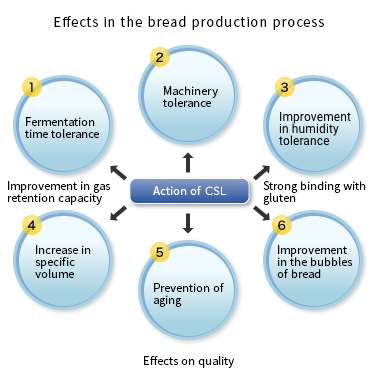

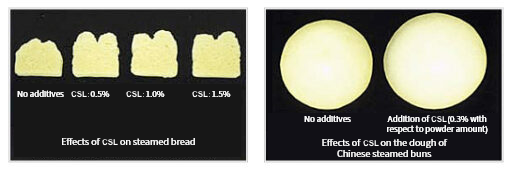

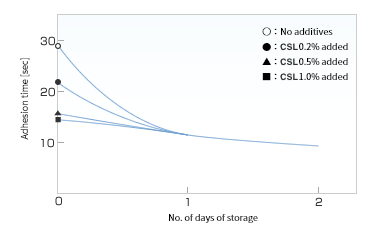

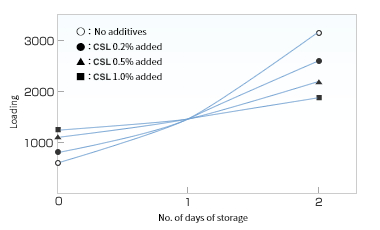

Salt of Stearoyl Lactate can exert an excellent effect of improving dough, because it improves the extensibility and stability of dough by acting on gluten, and reduces the damage caused by the excess or insufficiency of fermentation time or the mixing with equipment. It is suited for bread, confectionery, donuts, rice-flour bread, frozen dough, etc.

Calcium Stearoyl Lactate is an emulsifier that has been used as a quality improvement agent for bread from a long time ago.

Our company proposes products according to purposes of use.

- Calcium Stearoyl Lactylate: a quality improvement agent for bread, confectionery, etc.

- Sodium Stearoyl Lactate: for cosmetics